High Quality PP Plastic Hollow Sheet corrugated board

1. Definition

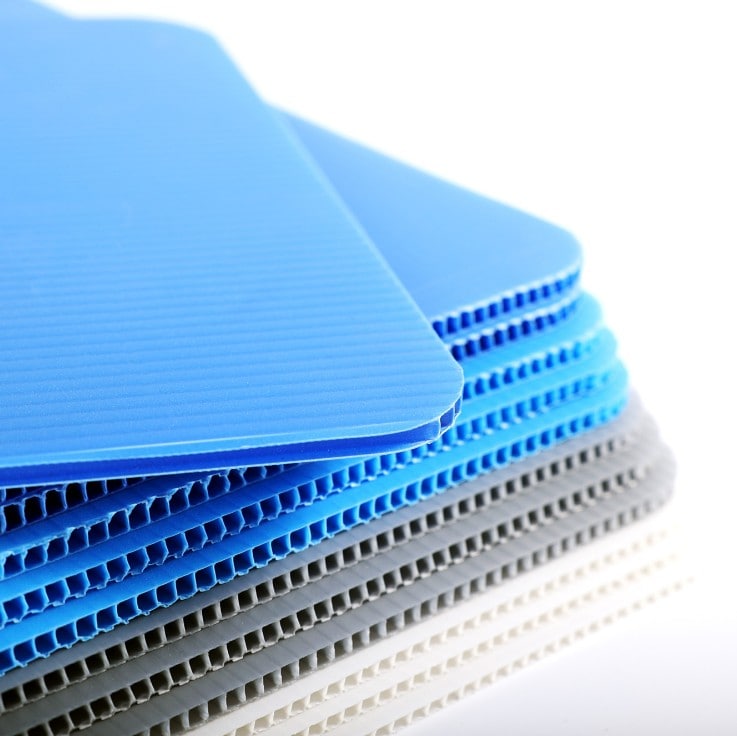

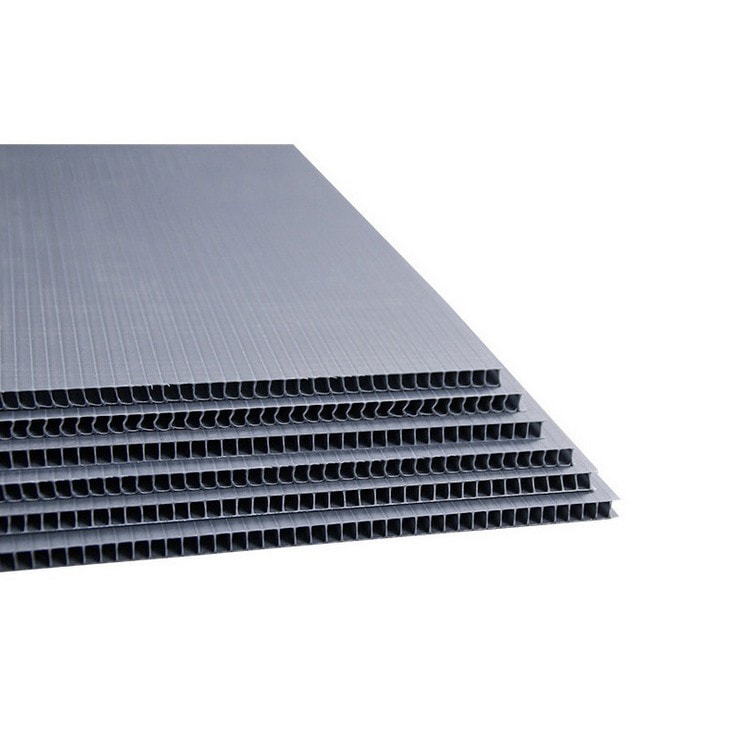

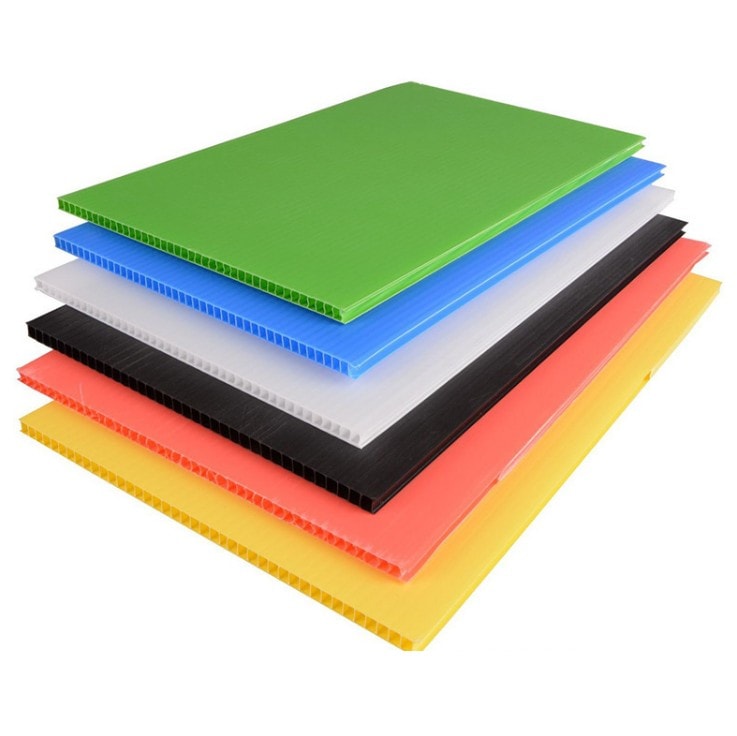

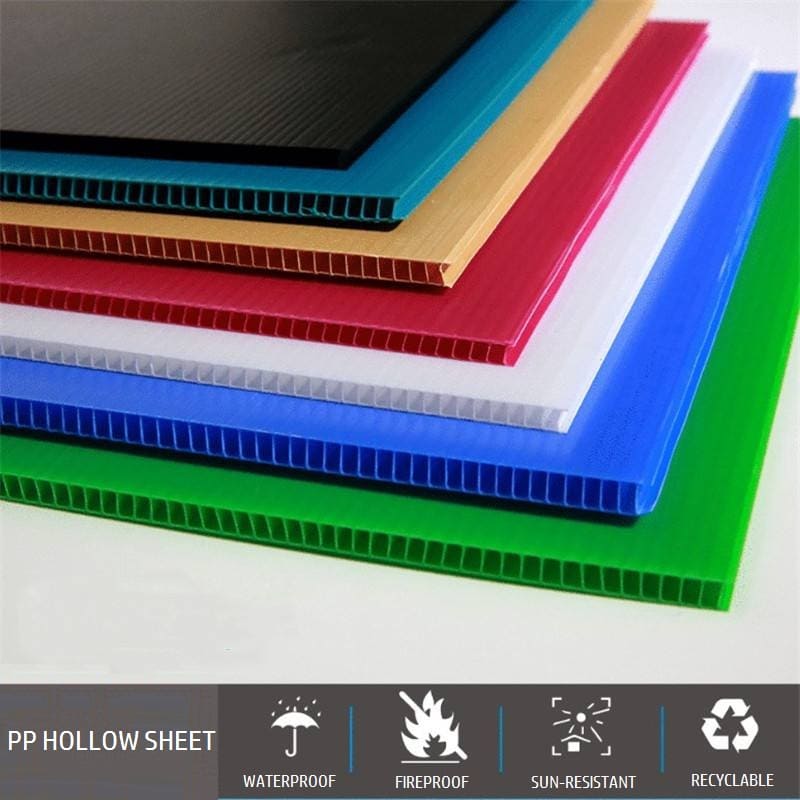

Hollow sheet, also known as plastic corrugated board, is a ligh weight, non-toxic, non-pollution, waterproof, shock-proof, anti-againg, corrosion resistance, non-slip, rich-colors of the new environmental friendly material.

Compared with trodational cardboard, the hollow sheet has much advantages of moisture-proof corrosion resistance, antistatic, flexible design. Widely used in electronics, industrial packaging, machinery, logistics, construstion, food, medicine, advertising, home appliances, decoration, cultural products, etc.

2. Quick Introduction about PP Hollow Grid Sheet

| Product Name | Plastic Hollow Sheet |

| Material | polypropylene powder |

| Technology | extrusion |

| Feature | Anti-ultraviolet, Antistatic, Non-corrosive,Non-slip |

| Color | Black, White, Blue, Green, Red, or Customized by Pantone |

| Thickness | 1.2mm – 15mm |

| Width | Customized Max 2600mm |

| Length | As required |

| Gram Weight | 2mm/400g, 3mm/450g, 4mm/650g, 5mm/850g or customized |

| Application | Packaging, Home appliance, Automobile, Advertising, Decoration, etc. |

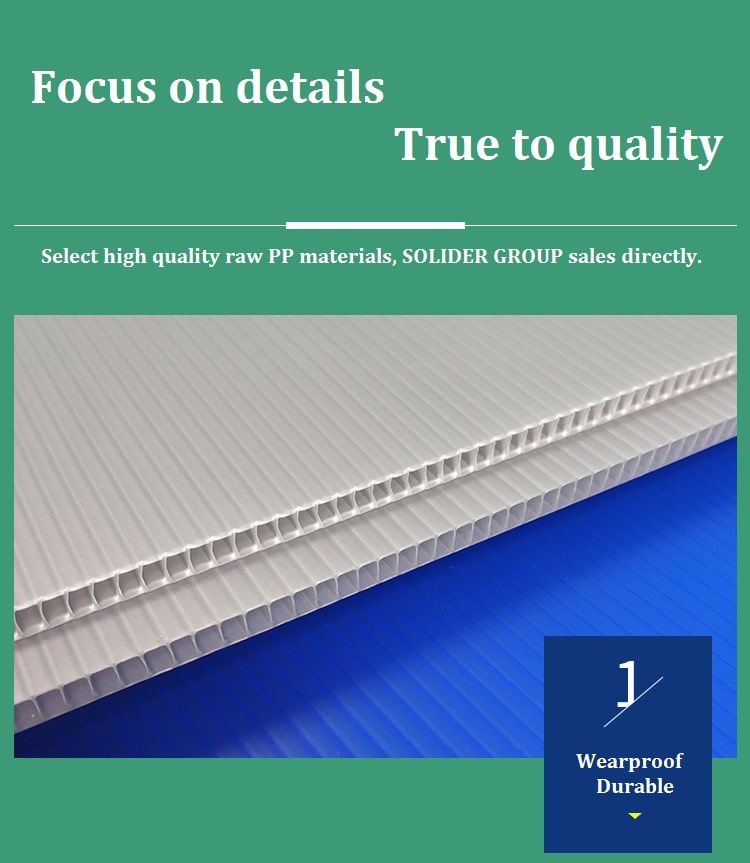

3. Product Details of Plastic Corrugated Sheet

The plastic hollow sheet has the characteristics of smooth, waterproof, oilproof, non-toxic surface, end products are bright colar, anti-ultraviolet, wear resistance, long service life, and low producing cost. Usually used for making turnover cartons for accessorie parts, beverage, jewelry, pesticide inner packing, instrument packing, electronic components packing base, goods partition, shelf floor, billboards, wall insulation panel, indoor ceiling, appliance backplane, like washing machine, water heater. Also used for car lining board, etc.

4. Packing & Shipping about Polypropylene Sheet

| Inner Packing | Plastic film |

| Outer Packing | Woven bag |

| Load Capacity | 9000-10000 sheets per 20ft container |

5. Company Information about Polypropylene PP Hollow Sheet

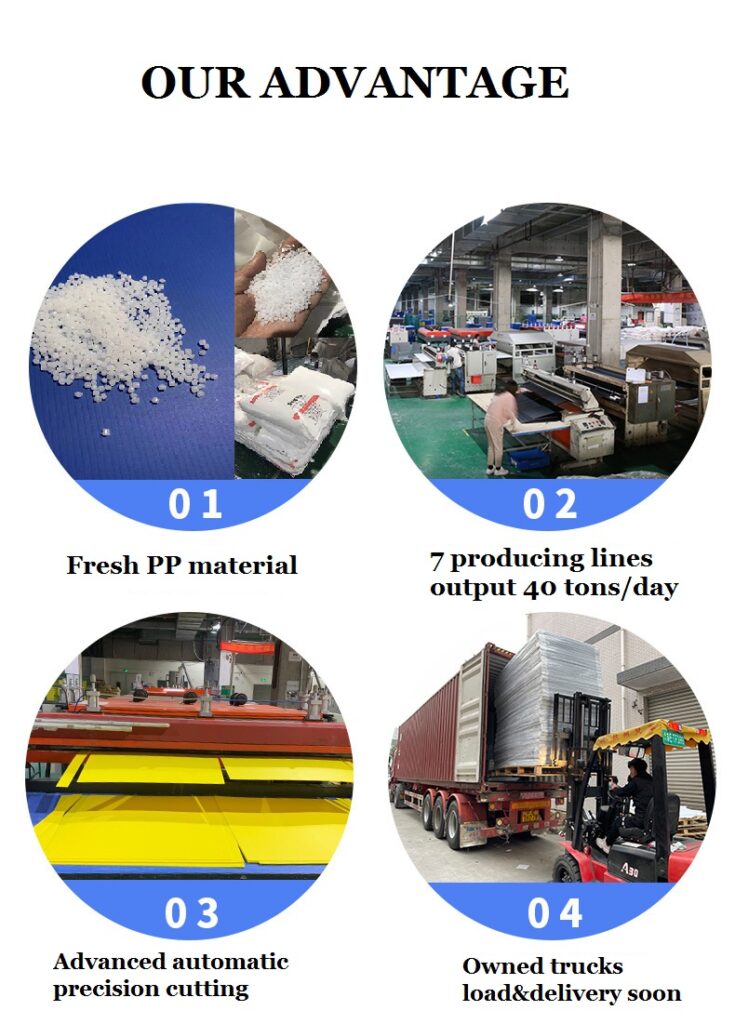

Every day SOLIDER Group can produce 60 tons of plastic hollow sheets, provides high quality hollow plastic sheets and honeycomb panels for large and medium enterprises, like home appliance, automobile, industrial packaging, advertising design, and other industries.

As a professional hollow sheets manufacturer, SOLIDER Group always adheres to a corporate purpose “Sincerely cooperating creates a win-win future”to provide every customer with excellent quality products and services. By constrantly increasing the investment of talents and funds, to achieve the improvement of efficiency and talent training, with a good brand to expand the global market.

At present, SOLIDER Group has 12 sets of extrusion lines, they are automation, stable operation, advanced process. 4 sets of screen printing machines, 2 sets of UV printers, 15 sets of indentation machines, 8 sets of automatic die-cutting machines, 12 sets of automatic balers. Total 20 different kinds of plastic sheets for exporting. Factory strictly implements the production quality standards and control precess, even from mold design to product selling, to make sure there is no a rejected product in the whole production process, to ensure the products with a good quality and a low price, Our plastic sheets are deeply loved by our customers.

By now, our high quality plastic hollow sheets are always exported to Europe, United States, Australia, South America, and other contries and regions. Dear friends, welcome to visit our factroy, and guide and negotiate business. Alternative Multi-style, free samples, are available. We are always here looking forward to a longterm friendly cooperation with you.

6. Contact Us for Hollow Sheet

If demand for our high quality plastic hollow grid sheet, please leave your inquiry details for a good price.